Manufacturing today demands precision, efficiency, and reliability. One technology that has transformed the way industries create complex components is EDM Wire Cutting. If you’ve ever wondered how intricate dies, punches, or press components are made with such accuracy, this guide will walk you through the basics.

What is EDM Wire Cutting?

What is EDM Wire Cutting?

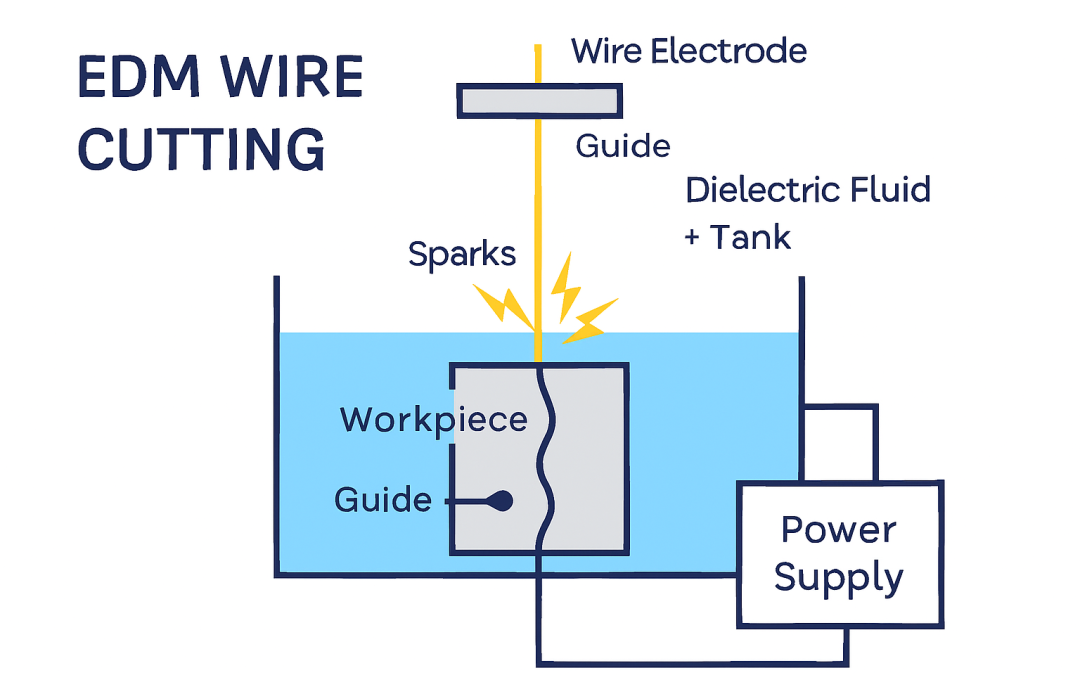

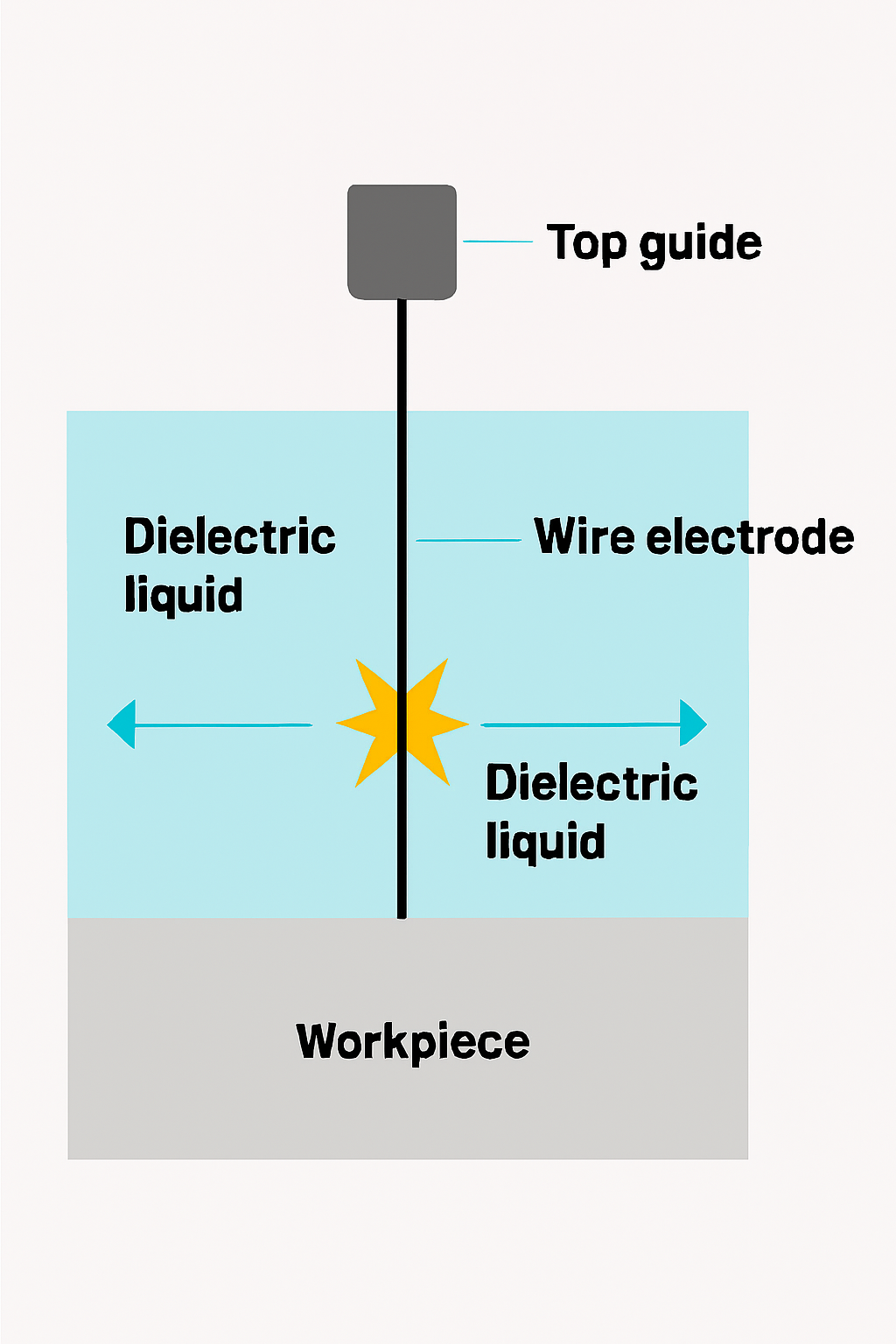

EDM stands for Electrical Discharge Machining. Wire cutting is a specialized form of EDM where a thin wire acts as the electrode. By passing electrical discharges between the wire and the workpiece, material is eroded with extreme precision—without physical contact.

This process allows manufacturers to cut complex shapes, tight tolerances, and hard materials that traditional machining struggles with.

How Does It Work?

How Does It Work?

- Wire Electrode: Usually made of brass or copper, continuously fed through the machine.

- Dielectric Fluid: Prevents sparks from spreading and flushes away debris.

- Controlled Sparks: Thousands of tiny electrical discharges erode the material exactly where needed.

- Computer Guidance: CNC programming ensures accuracy down to microns.

Think of it as sculpting metal with electricity rather than blades.

Why is EDM Wire Cutting Important?

Why is EDM Wire Cutting Important?

- Precision: Achieves tolerances as fine as ±0.002 mm.

- Versatility: Works on hardened steels, carbides, and exotic alloys.

- Complexity: Cuts intricate shapes, contours, and delicate geometries.

- No Stress: Since there’s no physical contact, there’s no mechanical stress or distortion.

For industries like automotive, aerospace, electronics, and tooling, this makes EDM wire cutting indispensable.

Applications in Manufacturing

Applications in Manufacturing

At Shakalya Enterprises, EDM Wire Cutting is at the heart of our operations. We use it to manufacture:

- Punches, dies, and strippers for turret punch press machines.

- Small press components that demand accuracy and durability.

- Custom tooling solutions tailored to client specifications.

This technology ensures that every component we deliver meets the highest standards of precision and reliability.

Choosing the Right Partner

Choosing the Right Partner

Not all wire cutting services are equal. When selecting a partner, consider:

- Experience: Years of expertise in precision manufacturing.

- Technology: Modern EDM machines and CNC programming.

- Quality Assurance: Certifications and compliance with industry standards.

- Customization: Ability to adapt solutions to your unique needs.

EDM Wire Cutting is more than just a machining process—it’s the backbone of modern precision manufacturing. By combining advanced technology with skilled craftsmanship, it enables industries to push boundaries and achieve results that were once impossible.

Looking for a reliable partner in precision wire cutting and tooling solutions? Contact Shakalya Enterprises today to discuss your requirements and see how we can help optimize your manufacturing process.

Contact Shakalya Enterprises today to discuss your requirements and see how we can help optimize your manufacturing process.